The target of this Third-Party inspection is checking the performance of the gas turbine. Also we test were to determine Overall mechanical operation and Rotor vibration.

What is a Gas Turbine?

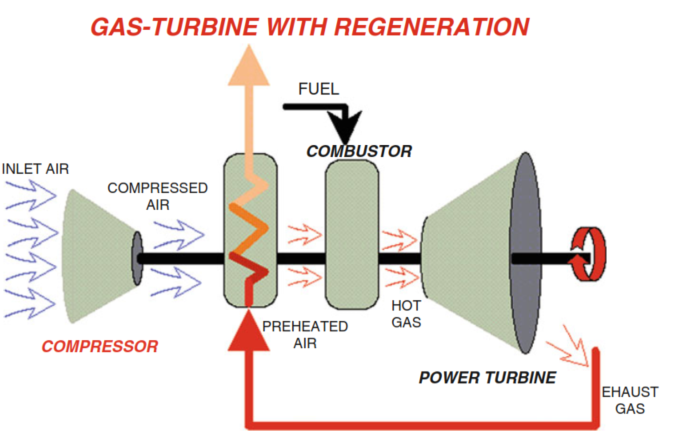

Gas turbine engines derive their power from the combustion of fuel in a combustion chamber and the use of rapidly flowing combustion gases to drive a turbine, much like high-pressure steam drives a steam turbine. In the gas turbine principle, a working gas (air) is first compressed by a compressor and heated by the combustion energy of the fuel. The working gas becomes the high temperature and the high pressure. The engine converts the energy of the working gas into the energy of rotation of the blades, exploiting the interaction between the gas and the blades.

What is the full speed no-load and Overspeed test?

Turbine Overspeed events lead to costly and dangerous catastrophic failures. Therefore, the Overspeed system has to be periodically tested to ensure the system has an adequate response time to protect the turbines, plants, and personnel. That is why the Third-Party inspection is vital.

Method and a practical description for Third-Party inspection

Date and location of gas turbine inspection

The inspection was carried out in July 2021 in France by the AROTEC Third-Party inspector. The inspection was started at 8:30 AM and it continued till 2 pm. According to the Inspection and Test Plans (ITP). Full Speed No Load Test (FSNL) and Clause Overspeed Test of the Gas Turbine Unit Rotor were done satisfactorily without any objection.

Purpose

The purpose of the factory tests was to determine Overall mechanical operation and Rotor vibration.

Full Speed No Load (FSNL) Test

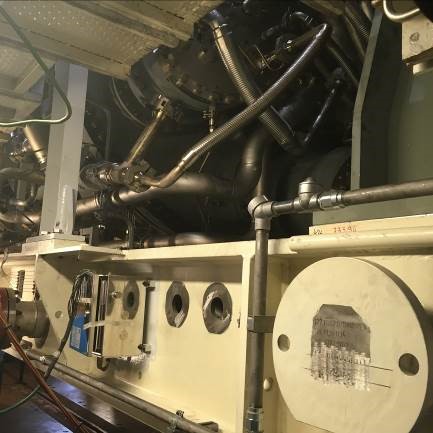

First, the unit was prepared for the test: Installation of the unit in the test facility, Gas turbine coupled to the starting system, Inlet and exhaust were connected, Test facility piping, electrical power and control cables connected to the unit, Gas turbine instrumentation connected, Test instrumentation installed on the unit and connected, Oil system filled and checked for leaks and correct operation, and finally Systems were checked.

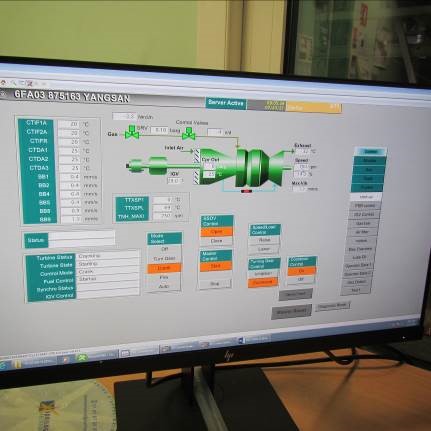

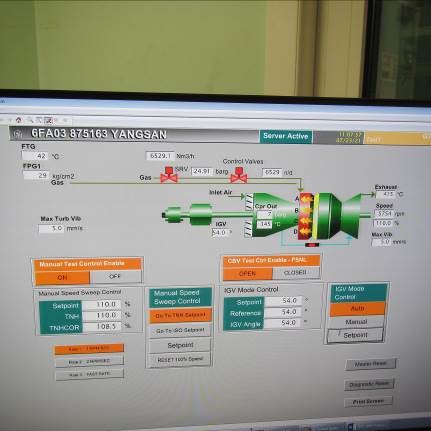

Purge: A purge sequence was carried out just before the start at 20% speed. Start: At 14 % nominal speed, the unit was fired at 29° IGV.

Vibration runs: The turbine was run at FSNL (5232 RPM), 54° IGV for at least 90 minutes to reach the stability criteria. 12.7 mm/s 0‐peak (0,50 inch/s 0‐peak).

The maximum measured vibration was below 6.4 mm/s, so the test was satisfactory.

Overspeed Test of GT (Assembled Condition) in gas turbine inspection

After FSNL, the speed was increased to 5757 RPM (110% of the TNH, and vibration was measured. The maximum vibration was below 6 mm/s; So it was Satisfactory.

The Performance test was mentioned in the 6F.03 GAS TURBINE FACTORY TESTS, but the vendor stated this stage was done on 22.07.2021. However, the vendor did it again at the end of the test as an internal test.

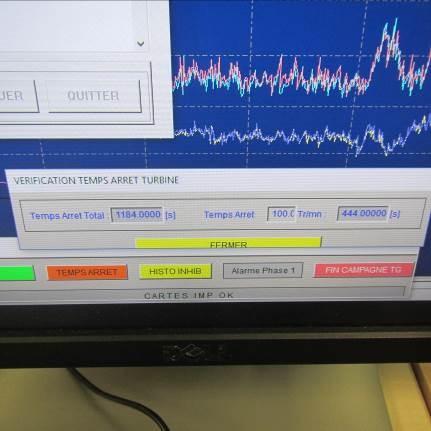

Then the Turbine stopped and the time of the 100 RPM to completely stop was measured, and it was 444 s, so this test was also satisfactory. It shall be more than 330 s.

Finally, the Turbine started again for cooling down and the Turbine connection parts have been checked, and no leak was detected.