Abstract

This article discusses “Impact Testing” as a destructive test, which is carried out to determine the mechanical properties. Testing procedures, achievements, and related common standards will be mentioned in this article.

Impact testing

Impact testing is a type of mechanical test which is performed on the sampled material to measure the amount of absorbed energy during fracture. This test is applied widely in various industries such as oil and gas, petrochemical, automotive, and also the equipment, which used in the powerplants, steel structures, pharmaceutical, food industries, and so on.

Since this method of testing is cheap and quick, it is performed on the used material for fabrication under the presence of the third-party inspection agency representative in the laboratory, and the results are reported to the customer.

1. What’s the purpose of Impact Testing?

The impact test is applied to predict the behavior of material against impact under actual conditions. The cracks, flaws, and notches affected their behavior. A swinging pendulum is used to impact the test piece and break the specimen. The initial and final height of the “tup” is recorded to calculate the absorbed energy by the brake’s specimen.

2. What are the types of impact tests?

The two below main impact test methods are used in the laboratories:

- Charpy Test

- IZOD Test

Both test methods are similar including a pendulum, which impacting to the test piece, however, the specimens are made in different methods and dimensions.

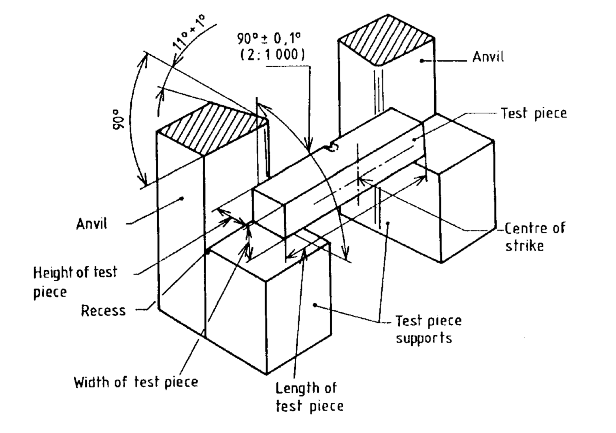

based on the EN 10045-1

3. Impact Testing procedure:

3.1. Test specimen preparation

The sampled material should be prepared according to the reference standard details including the length and square section side length, also the notch detail such as degree and depth were specified in the standard.

Moreover, the type of notch depends on the material. There are three types of notches: 1- Keyhole, 2- U-notch, 3- V-notch.

The keyhole and U are applied on the brittle material e.g., cast iron and plastic, and the V-notch is used for testing of the ductile material. The v-notch method is applied widely for weld testing.

3.2. How does temperature affect impact energy?

The temperature affects the test result so that by temperature decreasing the material behavior will be transformed from ductile to brittle. In fact, the amount of fracture energy is decreased in lower temperatures.

The test temperature is specified at 23±5 ℃ according to the ISO 148-1 and EN 10045-1 unless otherwise specified. For tests, which should be carried out other than ambient temperature, the specimen must be immersed in a cooling or heating liquid for a significant time to ensure that the required temperature is reached throughout the test piece.

3.3. Test Machine:

The test machine could be different based on the test method. It should be calibrated by an accredited laboratory to endure the results are trustable. The third-party agency representative controls the validity of the calibration certificate and it will be attached along with the inspection report to the client.

The test piece is put on the test machine and the pendulum is dropped to impact the specimen and the test piece is broken. If the specimen is deformed and not broken, the absorbed energy could not be determined (Acc to EN 10045-1).

4. Results’ Evaluation:

The result of the test specified the tested material is “brittle” or “ductile”. The absorbed energy of the brittle materials is smaller than the ductile materials.

The Charpy impact energy is affected by the below factors:

4.1. Yield strength and ductility

4.2. Notches

4.3. Temperature and strain rate

4.4. Fracture mechanism

It should be mentioned this test is qualitative and could be compared with the requirement of technical specification and it cannot be used to calculate the fracture toughness test.

Standards

- ASTM E28.07: Impact Testing

- EN10045-1: Metallic materials- Charpy impact test

- ASTM A370: Standard Test Methods and Definitions for Mechanical Testing of Steel Products

- ISO 148: Metallic materials — Charpy pendulum impact test — Part 1: Test method

- MPIF Standard 40: Standard test methods for metal powders and powder metallurgy products

- ASTM D1822 Tensile Impact Energy of Plastic | Test Machines & Equipment

- ASTM D256 Izod Impact Resistance of Plastics

- ASTM D4812 Unnotched Pendulum Impact of Plastic Test Machine

- ASTM D6110 Charpy Impact Resistance of Notched Specimens of Plastics

- ISO 13802 Pendulum Impact Test of Plastics | Machines

- ISO 179 Charpy Impact Strength of Notched Plastics | Testing Equipment

- ISO 180 Izod Impact Strength of Plastic | Test Equipment

- ISO 7765-1 Impact Resistance of Plastic Sheet and Film | Testing Equipment

- ISO 8256 Tensile Impact of Plastics Test Equipment