The Lube oil system is an important part of the compressor unit including the oil filter and accumulator, oil pump, oil mist separator, oil tank and oil tank heater, pressure safety- and control valves. Lube oil system inspection- Centrifugal Compressor as a necessary part of the TPIA activity on the high capacity compressors are described in this article.

It should be considered the separated lube oil system is applied to the high capacities compressors of the oil and gas or petrochemical industries, which due to the huge amount of oil flow rate, it’s designed separately. The below steps are common to be checked and tested on a lube oil system:

1- Chemical analysis & Mechanical Properties:

The chemical analysis and mechanical properties of the used valves, flanges, pipes, plates, etc. should be checked and reviewed if could be confirmed with the technical order and specification. The reviewed test reports are attached to the final data book.

2- WPS & PQR:

Approvement of WPS and PQR, moreover the qualification certificate of the welders is checked by a third-party inspector. All of the mentioned documents are attached to the welding book.

3- NDT examination:

The non-destructive test is performed on the seam welds. Before the hydrostatic pressure test, the welding should be checked for any unacceptable imperfections and discontinuities.

4- Hydrostatic pressure test:

The purpose of the hydrostatic pressure test on the lube oil system valves is to verify the strength under the work pressure. Therefore, the valves are tested on a higher pressure in comparison with the work pressure (e.g., 1.5 times the pressure rating at 15 to 120 seconds due to related NPS based on the ASME B 16.31)

5- Tightness test on the oil tank:

The tightness test is performed on the oil tank for any probable leakage or permanent deformation. After the tightness test, a visual inspection and dimensional check must be done to be ensured that no deviation or deformation has been occurred by the test.

6- Mechanical run test (Functional Test):

The lube oil system function test is one of the necessary tests of “Centrifugal compressor- Lube oil system inspection”. After performing the fundamental steps in this part, the lube oil system is run to check if each component works properly. All of the parameters are applied to the work conditions of the compressor based on the standard and recorded by the manufacturer as proof.

The standard API 614 (Lubrication, Shaft-Sealing, and Control-Oil Systems for Special-Purpose Application) is a common reference to achieve the mandatory requirements of the oil lubrication systems, which is also referred on the API 617. This international standard (API614) is intended to be used for services in the petroleum, chemical, and gas industries as well as other industries by agreement.

Oil system components downstream of the filters shall meet the cleanliness requirements of API Std 614 before any test is started.

7- Wiring and connectivity check:

The wiring and connectivity check is done based on the approved wiring diagram one by one, whether it complied with the reference diagram or not as a final check.

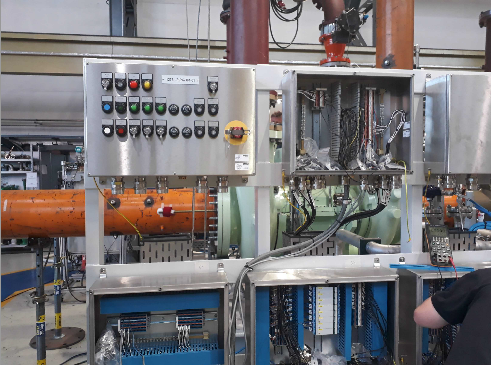

Junction box

8- Visual and dimensional examination:

The surfaces, painting, fittings should be checked to be ensured no deviation, dirt, surface flaws or imperfection exist on them. Moreover, the tagging, marking, and nameplates are controlled against the related drawing. The inspector compared the dimensions against the general arrangement drawing. Any deviation will be reported to the client for further corrective action.

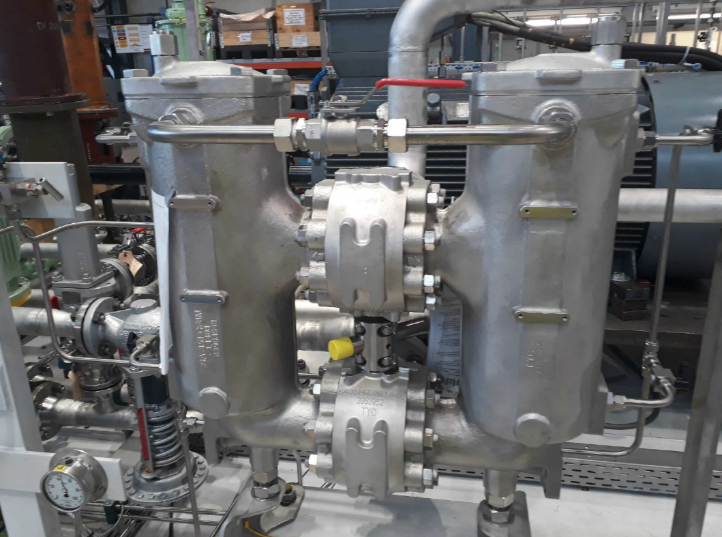

Visual inspection of the oil mist separator

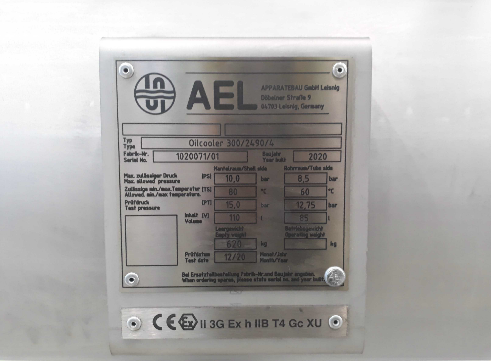

9- Lube oil system inspection-Centrifugal Compressor, Nameplate/Tag plate check:

The inspector checks the nameplate/Tag plate on the equipment and compares them with the specified requirement on the related drawing.

10- Color code and coating thickness (DFT):

RAL code check is done based on the datasheet/ technical order specification, also the coating thickness is measured by a calibrated instrument, and the third-party agency representative witnesses the activities to be ensured the standard requirements are applied.

Based on the compressor structure, relevant usage, and design conditions, maybe some fewer or extra tests and activities are to be carried out.

In the next article, the last part: “Centrifugal Compressor Final Inspection” and related activities, which are performed by the attendance of the TPIA inspector will be described.