Abstract

This article is mainly about the centrifugal pump(s) and the services, which could be provided by a “Third Party Inspection agency” during the production and as final inspection.

About centrifugal pump and related tests

Centrifugal pumps are applied in various industries such as oil and gas, power plant, water transmission, pharmaceutical, etc. to flow or circulate the water, oil, and oil products or other kinds of liquids.

In respect to the wide usage of centrifugal pumps, many standards have been issued by the international, American, European, or other authorized institutes and associations, furthermore, some purchaser use their technical specifications to reach the special technical parameters e.g., flow rate, head, efficiency, mechanical input power, etc.

There are various tests, which could be witnessed by Third-party inspection if the production complies with the reference codes, standards, and technical specifications or not.

The technical inspector observes the specified requirements, which have been specified on the reference documents through the calibrated measuring instruments, and the results are compared with the related acceptance criteria and the observation including the result, compliance, and probable deviations or discrepancies will be reported to the customer to achieve the best-controlled quality and quantity by third party inspection agency service.

General control of a centrifugal pump

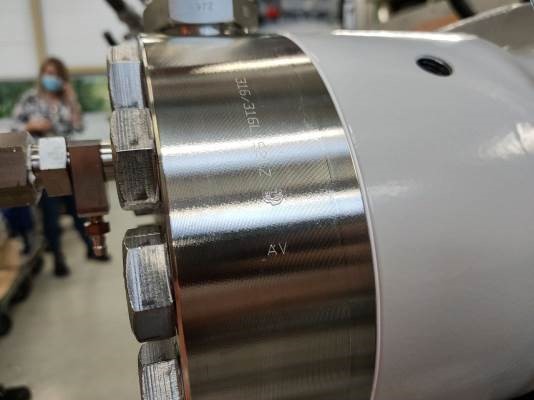

The TPI representative controls the identification of commodity through the tag-plate, nameplates, heat No. etc., and the Material control is applied on the fabrication process and final inspection of products to ensure the used material are complied with the requirements by control the material and review the mechanical properties and chemical analysis.

The inspector witnesses the visual aspect of pump parts internally and externally for any surface flaws, damages, welding imperfections, and the dimensions are compared with the general arrangement drawing.

The inspector checks the painting by dry film thickness check, RAL color code, or other requested painting tests.

Casing Hydrostatic Pressure Test

The hydrostatic pressure test is applied on the pump casing normally under 1.3 to 1.5 times of design pressure to detect any pressure drops, deformation or leakage if any. The inspection will be completed by the issuance of a test report along with the water analysis and calibration certificate of the used instruments during the test. The inspector checks the result whether complies with the acceptance criteria or not.

Vibration and Noise level measurement tests

The vibration and noise level measurements are witnessed by the third-party inspector based on the acceptance limits.

Why Performance tests for a centrifugal pump should be done?

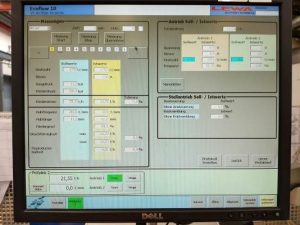

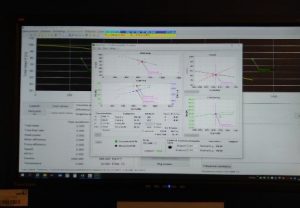

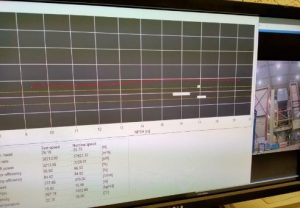

This test is carried out to determine that the head and flow of the produced centrifugal pump, as well as the power required, are per the technical specifications. Some points are recorded e.g., Shut off, Minimum stable continuous flow, Intermediate flow around 95% and 99% of rated flow, Intermediate flow between rated flow and 105% of rated flow, Approximately the BEP flow, End of the allowable operating region.

Finally, the results are reviewed by a third-party inspection representative and it will be mentioned in the inspection report for the customer’s information.

NPSH Test

The inspector witnesses the NPSH test to check if the results are complying with the requirements of the reference document. When the test result compares with the acceptance chart, it could be specified that the pump is working in the safe region properly without cavitation.

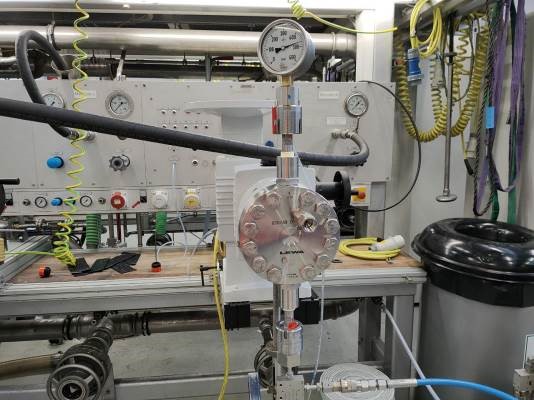

Mechanical run test

The mechanical run test is performed after the successful performance and net positive suction head test in a stable condition and all of the variables are measured periodically.

The pump is assembled on the test bench and ran under the presence of the third-party inspection expert inspector for a couple of hours.

During the test, some parameters such as ambient temperature, bearing and casing rising temperature, lube oil temperature, and pressure, etc., are measured.