Abstract

This article described the “Deluge System Inspection” by third party inspection agency “TPIA” with a focus on the fabrication process.

Introduction

A deluge Valve is used widely in fixed fire protection systems in the oil and gas, petrochemical, power plant industries as a critical part, and to be installed along with the main equipment, which has to be protected. Deluge systems are applied in the refineries, petrochemical plants, or tank units to deliver a large volume in a short time on a large area to extinguish or control the temperature of equipment in a safe range.

Due to the importance of this system, the customers ask the “TPIA” to survey the requirements and mandatory parameters, which should be considered by the manufacturer in the production process based on the international standards or their order and technical specification.

Based on the reference standard, design condition, and the usage of the deluge system various tests could be applied during the inspection. In this article, it was tried to describe some common tests, which are carried out on the skids.

1- How does a Deluge system work?

A deluge system is activated immediately after that a fire detector system commands through a signal because of a detected fire. The deluge valve distributes pressurized water to extinguish the fire rapidly. However, they are used not only for the fire protection system but also for the cooling system and dust collector.

2- Deluge System Inspection- General requirement

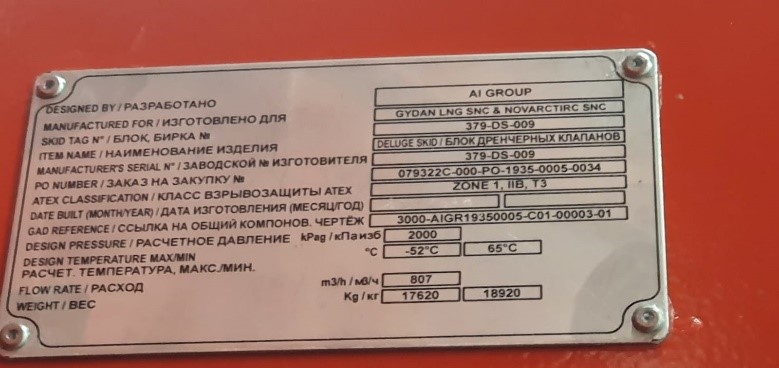

2-1- Identification check, tagging, and labeling control

The technical inspector checks the identification numbers, all nameplates, and tagging numbers based on the reference documents and general arrangement drawing.

2-2- Visual and dimensional control inspection

A visual inspection is performed on the equipment to be ensured of cleanliness, dryness, tightness, and preservation.

Any dust, grease, surface contamination, scratch, rust, or flaws should be removed from the components. All parts should be fastened properly and be dry, clean, and preserved in the good condition.

A dimensional check is performed on the components and skid on the length, diameters, height, width, etc., according to the approved drawing and related tolerances. The result of the inspection will be reflected in the inspection report to the customer.

2-3- Cables and cable trays verification

The cables and cable trays should be approved according to the reference documents. Cable tagging, size, their condition are to be controlled by the inspector.

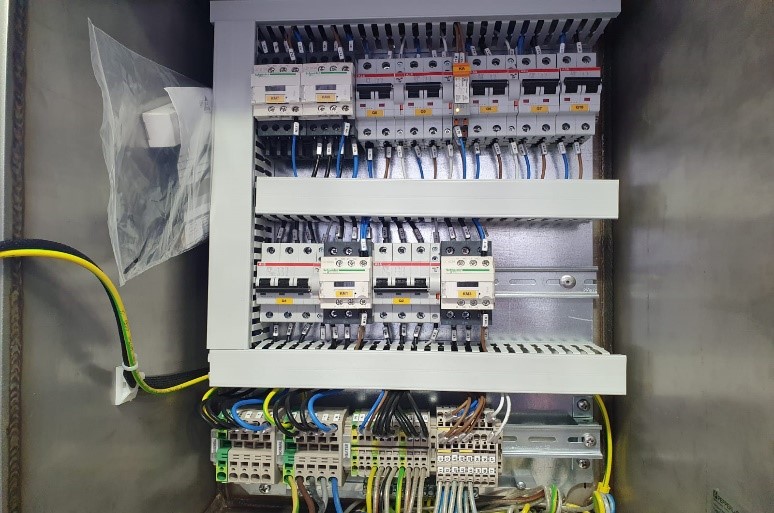

2-4- The wiring and Earthing check:

The wiring, cable tags, colors, and earthing are controlled as a part of “Deluge System Inspection” against the electrical drawings. The inspector reports any non-conformity or deviation for further needful corrective action.

2-5- Check of instrumentation and valve traceability

The inspector controls all of the components based on a list including the instrument name and tagging No. The existence of all parts should be verified in this step.

2-6- Painting inspection

The painting will be checked through the RAL coding, dry film thickness measurement, visual examination under the presence of the third-party inspection agency’s representative to control the painting quality based on the related acceptance criteria. The painting should be free of any defects and imperfections such as delamination, pinhole, blistering, touch up, and so on.

Moreover, the painting reports are reviewed including the painting process and parameters according to the painting procedure.

In the next part “Deluge System Testing”, some common testing will be described, which mentions the functional and operational tests.