Abstract

This article is mainly about the “Deluge System Testing” which is performed under the presence of the third-party inspection agency inspector to verify the components and system quality according to the standard and technical specifications.

Introduction

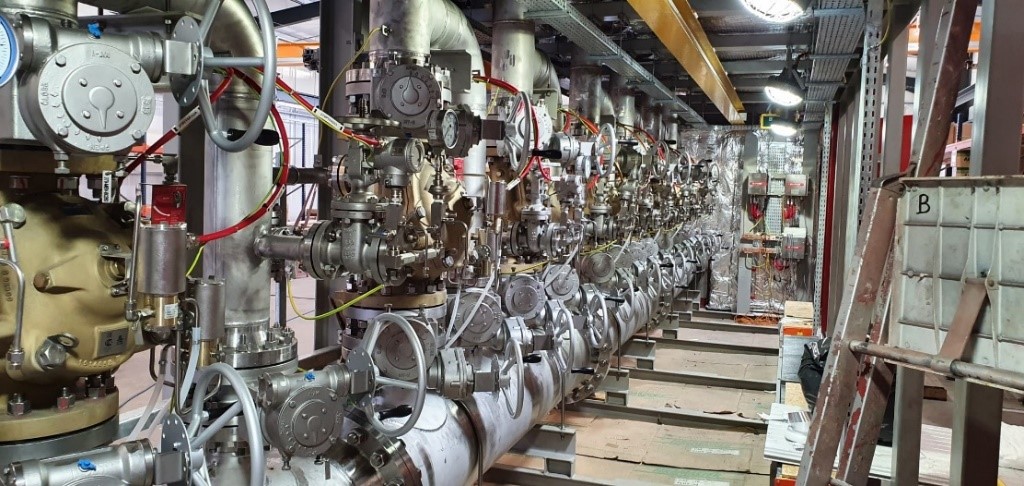

In the previous article, “Deluge system inspection” the general requirements were described, which a technical inspector should be checked on a deluge skid/deluge valve system. In this article, some common tests are described to ensure the quality of the used components and the whole system, whether it works properly or not.

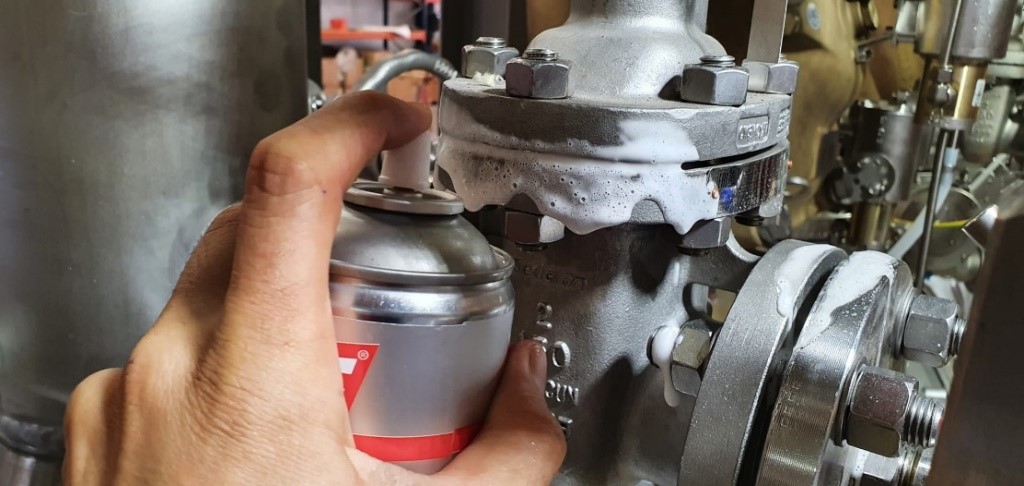

1- AIR LEAK TEST

The deluge system is to be pressurized by air based on the test procedure to indicate any leakage by using a foam spray. Leaked bubbles or pressure drops should be considered and compared with the reference standard to accept or reject the test.

2- Deluge System Testing- Material inspection

Material inspection including the raw material and welding consumable of the base plate and structural parts, pipes, valves, and accessories could be carried out under witness of the TPIA representative or to be reviewed due to the customer’s request and specified third party intervention in the inspection and test plan “ITP”/ quality control plan “QCP”.

Impact test, PMI, chemical analysis, or other mechanical tests are done on the above-mentioned parts according to the test procedure.

3- Why the Insulation Test should be carried out?

The purpose of the insulation test is to determine the resistance of electrical insulation material. A Potential difference is applied on two points on which the electrical insulation was installed, the little scaped current is measured and therefore, the resistance could be calculated.

4- ELECTRICAL FUNCTIONAL TEST

Lightings, junction boxes, circuit breakers, and other electrical are checked by the attendance of the inspector for functional tests.

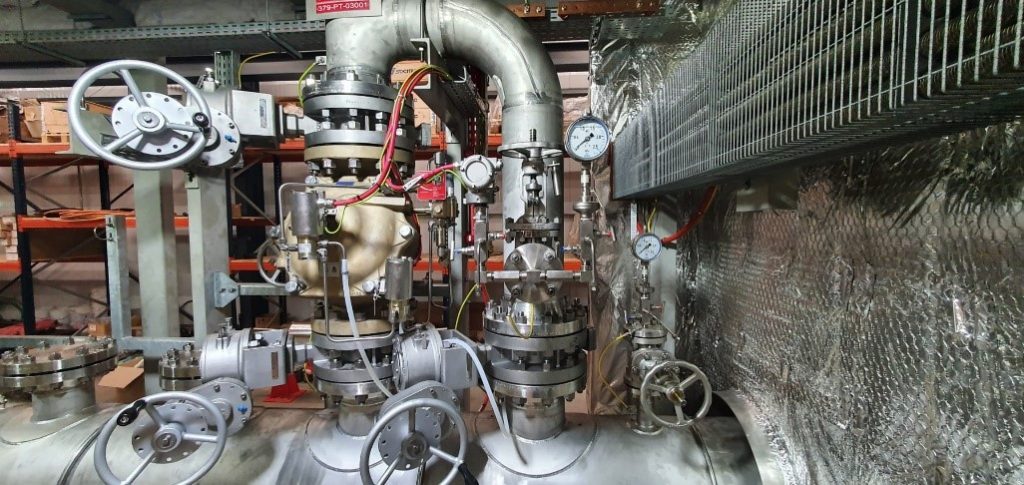

5- Check Of Pressure Transmitters And Pressure Gauges – Functional Test

Temporary Manual valves are to be mounted at the Deluge Valve Water outlet.

A static pressure shall be applied to the firewater inlet. So, the pressure transmitters and pressure gauges are tests and the result of the functional test will be reported by the inspector.

6- Hydrostatic test

The hydrostatic pressure test should be performed on the deluge system to ensure the strength of valves, pipes, joints, or any other components, which are pressurized during the related function. The deluge system is filled full of water and the outlet is closed, then the pressure is increased to specified test pressure in the test procedure. Any pressure drop or leakage should be in the acceptance limit range (if it was allowed) and no permanent deformation should be done.

7- Seat Leak Test

The seat leak test is performed on the deluge valve under test pressure, more than maximum allowable pressure (e.g 1.1× maximum allowable pressure acc to the API 598) for a specified time duration. No leakage from the stem, and packing is allowed and the amount of leakage from sealing should be compared with the acceptance limit.

8- Functional and simulation test

Functional test of each separate part is performed such as lighting, earthing continuity checking lighting functional Test including emergency lighting, Heater Functional test, and so on to ensure all part work properly based on the procedure. The third-party inspector witnesses the tests and reports the result of the inspection to the customer.

Deluge system testing could be included more tests due to oprational status and design of the system. Moreover, each component such as vavles, flanges, pipes, measuring instruments and so on should verified and approved by the related standards and this testing only provide the functional and oprational testing of these system.