Heat exchanger-final inspection is fulfilled by TPIA on the last step of the production to cover the packing, marking, and loading supervision inspection.

Previous article “Heat exchanger inspection” describes the inspection activities and tests, which are performed commonly by the third-party inspection agency.

1- Final vessel dossier

The final manufacturing dossier including all verifying documents is provided by the manufacturer and submitted to the third-party inspection representative to review and stamp them. Finally, the endorsed dossier is conveyed to the customer.

2- Final inspection

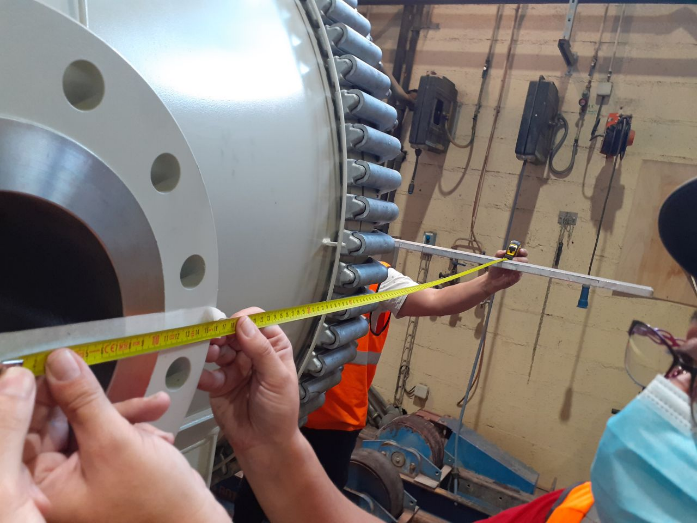

Final inspection step is carried out by technical inspection based on the ITP requirements.

The technical inspector controls produced equipment visually for any unacceptable dirt and contamination, surface, welding or painting imperfection, and defects.

Moreover, a dimensional check is done to check the finalized item’s dimensions according to the GA drawing each non-conformity is reported to the client and should be traced and solved by the manufacturer.

3- Pre-shipment inspection

After the successful final inspection, the commodity will be prepared for packing, marking, and loading according to the purchase order/ contract between vendor and customer and QCP/ITP detail and related procedures.

Heat exchanger-final inspection- Packing:

Based on the packing procedure proper preservation is done to prevent any damage during the shipment by fixing the heat exchanger and related parts on the packages with a belt, covering them with plastic or foil coverage, and packing them with a wooden box or carton.

Heat exchanger-final inspection- Marking check:

The markings and symbols are controlled by the third-party inspection representative including the shipping marks e.g., handling marks. Also, the label information is checked such as package size, net weight, gross weight, destination, manufacturer, customer, etc.

As an important step of pre-shipment inspection “Marking and labeling “could be mentioned. Labels often are including the hazards associated with the package, and markings ensure the shipment is handled properly and in the recommended method by the manufacturer to prevent any accidents. As such, they must be applied appropriately, reflect the correct information, and comply with regulations.

In case of spare parts have been ordered, these items are checked by the inspector in accordance with the purchase order and packing list.

Finally, the packing list is signed by the vendor and TPI inspector and delivered along with the pre-shipment inspection report to the client.

Moreover, if requested the loading supervision could be surveyed by third-party inspection representative to check and report the requirements according to the client’s advice and instruction and against the reference documents.

In loading supervision, the inspector commonly reports whether the loading has been complied based on the loading procedure or not, the container condition (inside and outside), preservation and fixing of the packages sequences on the container, ISO marks on the container, truck No., etc. finally the container is sealed under the presence of the TPIA inspector and vendor’s representative and maybe other parties’ persons.

Standards:

Due to the heat exchange usage, flows, and type of heat exchanger various codes and standards are applicable. Here are some common standards that could be found:

- API RP-586 Section 1: Heat exchanger tubing inspection

- API 660: Shell-and-Tube Heat Exchangers

- PED 2014/68/EU: PRESSURE EQUIPMENT DIRECTIVE (PED) 2014/68/EU

- DIN EN 13445: Unfired pressure vessels

- DIN EN 13480: Metallic industrial piping

- ASME Sec II: Materials

- ASME Sec V: Nondestructive Examination

- ASME Sec VIII DIV.1: Rules for construction of pressure vessels

- ASME B31.3: Process piping