Abstract

This article discusses “Tensile Testing” as a destructive test to achieve some mechanical properties and behavior of the sampled material.

Tensile Testing (Introduction)

Tensile Testing that named also tension testing or Ultimate Tensile Strength (UTS) is a kind of destructive test in material science by preparation of a test sample and application of the tensile force until failure.

The tensile test is applied in various industries in the fabrication process based on the determined tests in the related codes and standards in the initial part of the production to control the material, which will be used. Third-party inspection agency representative as an independent side witnesses the sampling and tests and reports the testing to the customer to ensure whether the testing progress and the test results are based on the standard and approved procedure or not.

When is the tensile test used?

Generally, this test is applied to the sampled material to measure the tension before the Test coupon to be broken. Some mechanical properties could be extracted as a result of this test such as ultimate tensile strength, breaking strength, maximum elongation , and reduction in area. Moreover, some extra properties could be determined by achieved parameters in the first step i.e., yield strength Young’s modulus, Poisson’s ratio, and strain-hardening characteristics.

2- Procedure

2-1- Preparation tensile specimen:

The specimen preparation could be different due to the purpose of the test and reference standard. The Test coupon has two shoulders and a gauge between those. The shoulders are made to be gripped on the test machine.

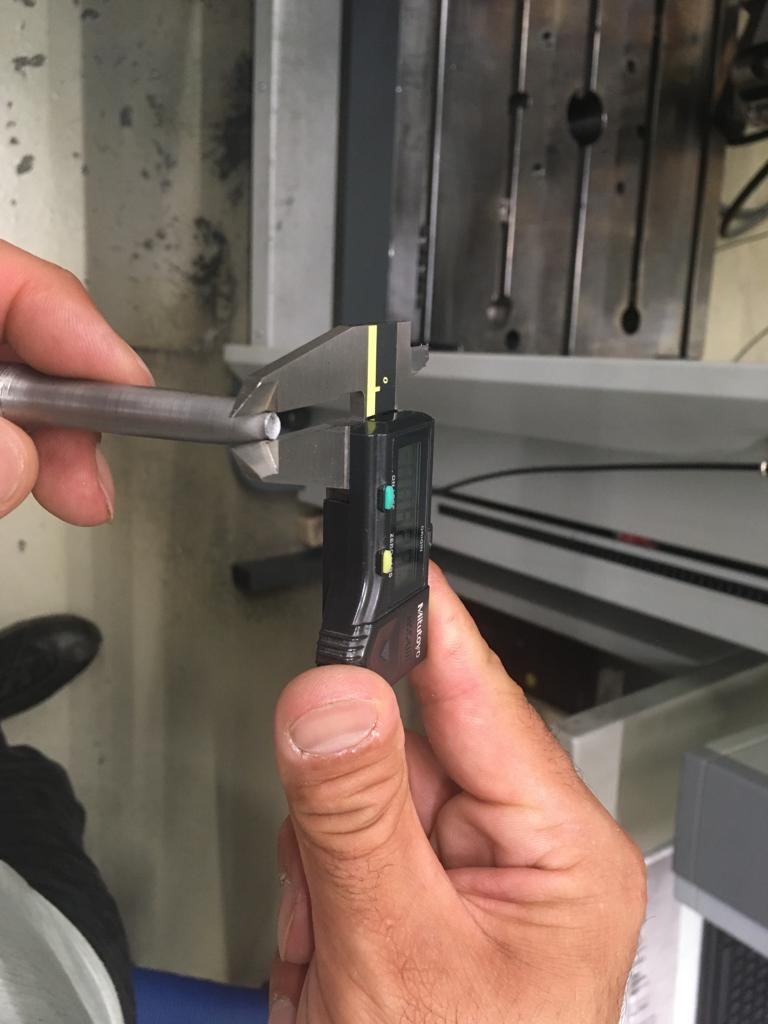

The technical inspector controls the specimen dimensions such as gauge length, diameter/width, fillet radius, overall length, length of grid section, and so on, also preparation method based on the reference standard.

2-2- Application of tensile force:

The specimen is held by the top and bottom grips of the testing machine. Then the tensile force is applied and the amount of force and displacement is measured continuously during the test. The force increased slowly till the specimen to be failed and broken.

2-3- Tensile Testing (Result calculation and evaluation):

The final length of the failed specimen is measured and compared with the initial length. Moreover, the original cross-section measurement is also compared to the final cross-section to obtain a reduction in area.

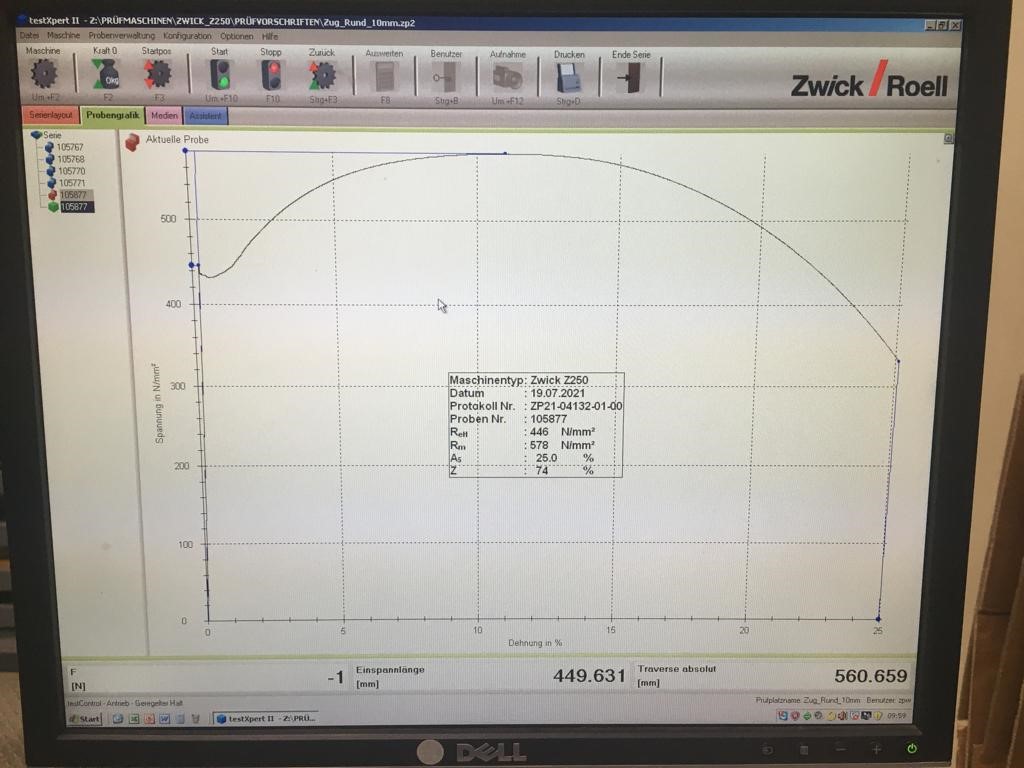

The Stress-Strain curve is obtained from the applied tensile force by the testing machine and the displacement is recorded continuously. Calculated mechanical parameters are visible on this chart.

3- Standards for Tensile Testing:

Some common standards are as below:

3-1- Metals

- ASTM E8/E8M-13: “Standard Test Methods for Tension Testing of Metallic Materials”

- ASTM E21: Standard Test Methods for Elevated Temperature Tension Tests of Metallic Materials

- ISO 6892-1: “Metallic materials. Tensile testing. Method of test at ambient temperature”

- ISO 6892-2: “Metallic materials. Tensile testing. Method of test at elevated temperature”

- JIS Z2241 Method of tensile test for metallic materials

- MPIF Test Standard 10: “Method for the Tensile Properties of Powder Metallurgy (PM) Materials” Standard Test Methods for Tension Testing of Metallic Materials”

3-2- Composites

- ASTM D 3039/D 3039M: “Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials”

3-3- Flexible Materials

- ASTM D638 Standard Test Method for Tensile Properties of Plastics

- ASTM D828 Standard test method for tensile properties of paper and paperboard using constant-rate-of-elongation apparatus

- ASTM D882 Standard test method for tensile properties of thin plastic sheeting

- ISO 37 rubber, vulcanized or thermoplastic—determination of tensile stress-strain properties