Abstract

This article is describing the Valve inspection by TPIA “Third Party Inspection agency” during the production and as final inspection. So many tests could be performed due to valve type and related standards. It is tried to mention the general and common tests, which are carried out on the valves.

Introduction

The valves including the various types, always applied to on/off, regulate, and control also direct the flow of gas, liquid, or fluidized solids or slurries. The valves are used in industrial and home equipment widely.

Many international codes and standards could be applied to control the requirements of the valves due to valve type, usage, design, service condition, etc., The “Third Party Inspection” as an independent agency has an important role in the production process and final inspection to control based on the related standard, technical specification, moreover the inspection and test plan/ Quality Control Plan, which are confirmed by the customer as a reference document.

Material test

The material, which should be applied to fabricate a valve part, such as body, shell, stem, body, bonnet, etc., could be reviewed or witnessed by a third-party inspection agency on chemical analysis and mechanical properties tests to ensure that, the material complies with the technical specifications on datasheet/ ITP.

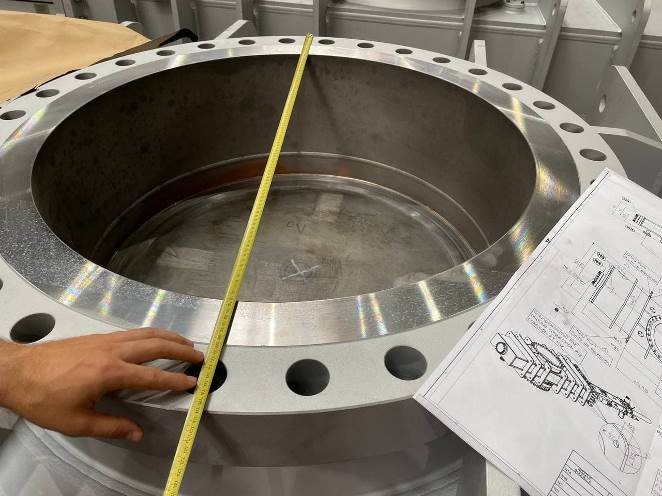

Visual inspection, dimensional check

The inspector performs the visual inspection to control if the items are clean, dry in proper status, and without any dust, grease, surface flaws, welding imperfections, or other similar unacceptable deviation or discrepancies.

Moreover, the dimensions are checked according to the general arrangement drawing on length, diameters, hole sizes, or other dimensional parameters to be verified by the TPI inspector.

Hydrostatic shell pressure test

The shell should be tested with water under specified pressure and time duration, any deformation, leakage, or pressure drop will be measured and compared with the acceptance criteria and acceptance limit to accept or reject the tested valve.

Leak tightness seat test (Pneumatic test)

The pneumatic test is a type of test to specify the valve parts’ tightness is properly done or not. The measured leaked bubbles could be accepted or rejected due to counted value and acceptance criteria.

Body leak test

The body leak test is applied by helium gas under specified pressure on the standard. The valve should be blanked on all connections, then the helium is blown to the valve, and the leaked helium through the welding joint, body, etc., is measured by a calibrated helium gas detector probe and the measured values are compared by the TPI inspector with the related acceptance limit.

The manufacturer issues the leak test report as proof of the test to be signed and submitted to the customer.

Functional test

The functional test is performed to be ensured that the valve works properly. This test could be different due to the type of valve. Response time tests and operability could be checked on the motor operative valves.

Marking and Identification

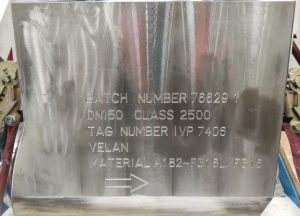

The technical inspector verifies the identification number of the valve on the body and tag plates and traces them on the document.

The necessary marking should be engraved and observable on the valve body, such as flow direction, valve class, serial/Tag No. nominal size, material, manufacturer’s name, and so on.

The nameplate should comply with the drawing including all specified information and dimensions.

Painting inspection

The painting inspection could be carried out during the production processes such as sand/shot blast or as a final inspection, e.g., adhesion test, color RAL code check, dried film thickness test “DFT”, holiday test, based on the mandatory tests which are specified on the standard or extra tests by request of the customer.

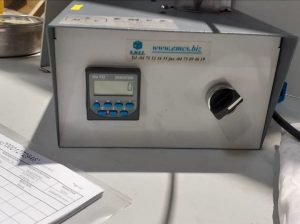

Why the measuring instruments should be controlled?

During the technical inspection, lots of tests are performed under the witness of the third-party inspection representative. The test results could be trustable, just when the measuring instruments have been calibrated on an authorized third-party Laboratory according to the ISO 17025 requirements.

As an inspection service, the inspector will be controlled the validity of the measuring instruments by checking the calibration label and calibration certificates.